Smart Manufacturing

Advanced Manufacturing

In recent years the manufacturing industry is considering new investments aimed at upgrading and optimizing factories and supply chains from a global view point to strengthen its presence in the globalization of business environment.

In factories, i.e. the bedrock of business, implementation of manufacturing innovations with IoT (Internet of Things) is required in accordance with development of Industrial IoT technologies in the world such like "Industry 4.0" proposed by German government and industries.

Industrial Manufacturing IOT

-

General Manufacturing Operations

As a pioneer of the measurement & control by micro electronics, CONTEC offers a vast lineup of reliable and high performance products that can support various sensors and actuators. Based on its expertise in highly reliable technology with electronic devices for factory automation since our establishment in 1975, we provide FA control equipment and systems that can optimize automation, research and development, production processes, and maintenance.

-

Automotive Industry

Automotive and related industries are the driving force of the manufacturing industry. Possible improvements are frequently identified at each processes in manufacturing line. Not only the automation of each process but visualization, improve work efficiency, quality, traceability, and logistics by ICT are being promoted.

Open technologies are being adopted into production facilities of automotive industry alog witgh advancing IoT technologies and Industrial IoT platforms like “Industrie 4.0”.

Applications

-

AI-Based Equipment Error Detection Using Current Sensors

Create an AI-based error detection system easily and quickly by linking CONPROSYS with partner solutions.This makes it possible for customers to collect data, select analysis models, and register teaching (normal) data or additional teaching (accuracy improvement) data on their own.

-

Reduce Operation Management Costs & Enhance Operational Efficiency

By utilizing IoT technology, it is possible to achieve reductions in operation management costs for environmental testing, while also enhancing their efficiency. This system enables all aspects of environmental testing—including operation monitoring, error notification, and reservation management—to be performed by connecting CONPROSYS™ IoT devices to X-ray testers, thermostatic chambers, vibration testers, and impact/drop testers and compiling all operational data in a server.

-

CONPROSYS™ IoT Solution Three-Phase Motor Breakdown Prediction Monitoring

The Insulation Deterioration Monitoring Module from CONPROSYS™ is a revolutionary product for measuring the insulation resistance of three-phase motors that otherwise cannot be measured without stopping the device. With the CONPROSYS™ Insulation Deterioration Monitoring Module, constant motor insulation deterioration monitoring is possible for three-phase motors, allowing for detection of possible signs of failure.

-

Improvement of Production Capacity by Introducing IoT for Existing Facilities (Production Line)

This system realizes monitoring of the whole factory operation by supervisory software.

The "CONPROSYS series", developed by CONTEC’s over 40 years technical knowledge and experience, enables integration of machine to machine communication (M2M) by "OPC UA", a field network standard recommended by Industry 4.0.

The system enables integration of old-type machine tools with MES (Manufacturing Execution System) by using the M2M controller with built-in OPC UA server. Work load balance and production capacity improvement will be achieved by clarifying the capabilities of all production facilities in the factory.

-

Operation Monitoring of Production Facilities

The system monitors the operational status of old-type facility that has no communication capabilities using various sensors and relays. If it uses PLCs, detailed information can be collected via PLC communication.

The collected data can be transmitted to upper-level servers using HTTPS data post or MODBUS/TCP slave function. Monitoring of facilities is possible on Web browser of Laptop PCs or Tablets by making web-based monitoring screen on CONPROSYS HMI built in the controller.

-

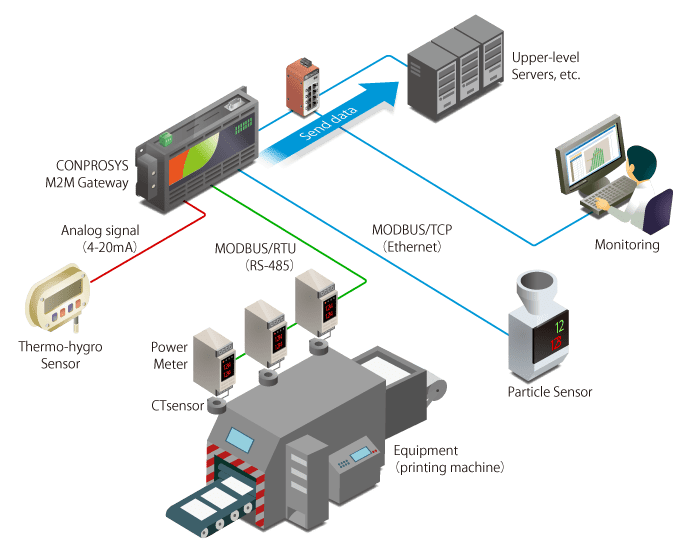

Measurement of Energy Consumption and Environment of facilities

The CONPROSYS Gateway series supports data collection using MODBUS communication.

MODBUS communication is available with many devices including power meters, sensors, and remote I/Os. These devices can be used to monitor the energy consumption of equipment and measure the environment.

-

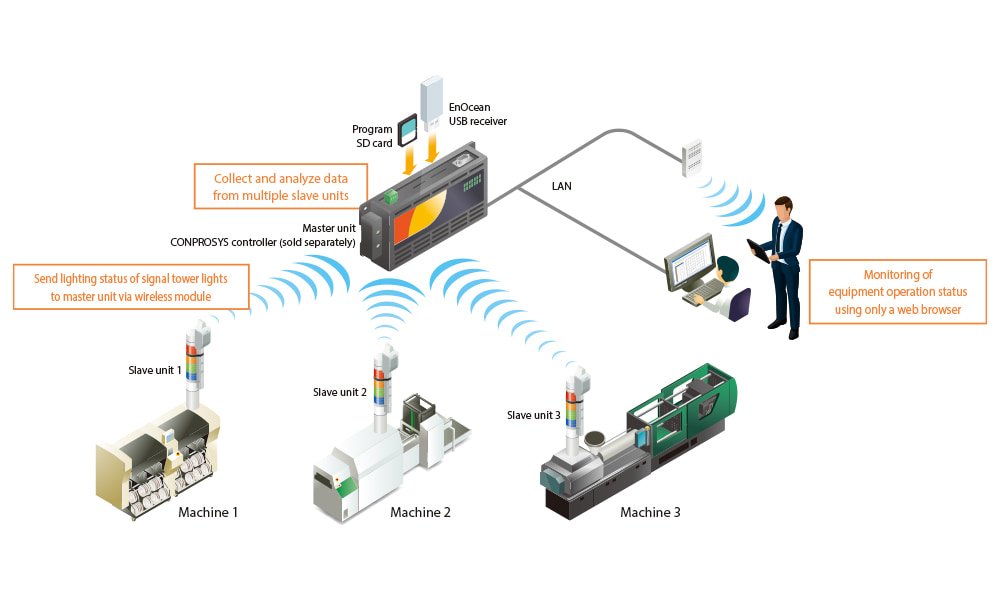

Visualizing Operation Statuses

Signal towers make it possible to visualize current equipment operation statuses. Signal tower monitors are devices that monitor the lighting status of a signal tower and save the transmitted data. Devices (slave units) can be installed to signal towers already in use, with the simplest installation configuration taking only 10 seconds to complete. Wireless communication between master and slave units eliminates the need for complicated wiring work. Optimize maintenance cycles using breakdown prediction and preventive maintenance while simultaneously shortening downtime to improve operating ratios, take advantage of labor-saving measures, and address insufficient human resource issues.

-

Operator Attendance Management Using IoT Technology

We have designed a system for managing the attendance of cell production operators. This was done by installing motion sensors and IoT devices in the cell production area to collect information regarding operator movement. By using the CONPROSYS™ telemeter system (CPS-TM341 series) and CONPROSYS™ nano (remote I/O), centralized monitoring of 20 interspersed areas is possible, with collected data able to be viewed anywhere using a Web browser. Collected data can also be downloaded and tabulated using worksheet software such as Excel to enable analysis of times, frequencies and time zones, etc., for operator attendance and unattendance.

-

Alarm E-mail Notification System

When errors such as defects during inspection, an e-mail alarm is sent to the personnel of the previous processes about that. Even when he is away from the station, other related people can receive immediate, real time notification about the occurrence of abnormalities.

Solution Enquiries.

Advance your business today. Contact us now to learn about Contec solutions that can support your business transformation.